News

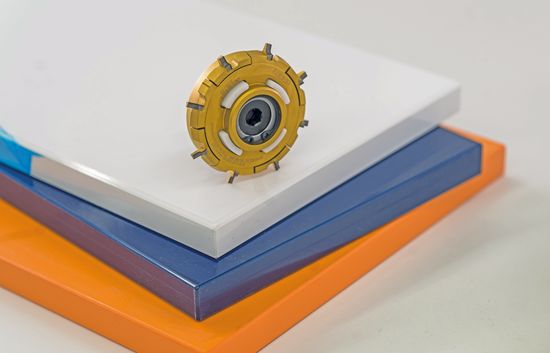

The new flexClick cutter is used for rounding and chamfering plastic edge bands and MDF edges in furniture production.

The innovation of this diamond-tipped cutter is the automatic adjustment option between profile 1 and profile 2.

It is based on the ballpoint pen principle and works mechanically. This means that customers get twos profile with one tool. Switchover between profiles is done by pressing the tool at standstill on a copy wheel, thus actuating the mechanism.

No complicated motor controllers are required. The new cutter is available for machines from Homag Kantentechnik GmbH and can also be used without problems on standard motors of existing machines. The flexClick cutters are delivered along with the adjustment mechanism.

This option of the dual-profile technology is ideal for small edge banding machines and companies that want to produce small lot sizes with low set-up requirements.

A patent application has been filed for this innovative and at the same time easy-to-use principle for profile change together with the machine manufacturer Homag.

The flexClick edge rounding cutters are available from stock with a few combinations for profile 1 and profile 2. Further profile combinations are available upon request.

News Overview

-

Mar 28, 2024

Shank-Type Cutters , Tool News

New nesting cutter Z4+4 based on Fibonacci:

Slim, swift and stable -

Dec 6, 2023

Circular Saw Blades , Tool News

Interview: HW-panel sizing saw blade

“Q-Cut G6 Edition” with tool life -

Oct 25, 2023

Circular Saw Blades , Tool News

LEUCO nn-System DP flex -

Now with new topcoat coating -

May 4, 2023

Shank-Type Cutters , Tool News

DIACURVE: Novel nesting cutter

Perfect cut, easy to handle -

Jul 1, 2022

Boring Bits , Shank-Type Cutters , Tool News

A tool for every application, flexibility as standard -

Sep 22, 2021

Shank-Type Cutters , Tool News

LEUCO t3-System cutters with triangular turnover knife inserts -

Jun 1, 2021

Circular Saw Blades , Tool News

Q-Cut panel sizing saw blades from LEUCO: Best finish-cut quality