LEUCO p-System

Peel it, see it, feel it!

The revolutionary wood processing

technology by LEUCO.

10 Jahre p-System Patent

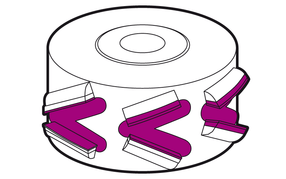

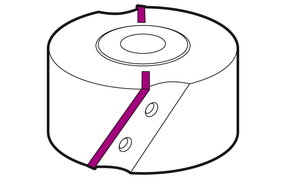

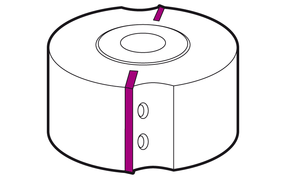

In 2010, LEUCO filed a patent for tools with a shear angle in the range ≥ 55° – 90° and called them “LEUCO p-System”. This innovation means far more than just milling. The fibers of the material are “peeled” to knife-like sharpness with a pulling cut. LEUCO wood processing with p-System tools is therefore called “peeling”. All LEUCO diamond-tipped p-System tools in the catalog program have a shear angle of 70°.

Peel it! See it! Feel it!

see it: a brilliant cutting quality that is visible

feel it: generally a significantly longer edge life than ordinary DIA tools with a positive effect on the budget

see it & feel it: extraordinary application possibilities which save machine times, machine downtimes and/or post-processing times and which are surprising and ultimately lower the costs

- With the LEUCO p-System jointing, grooving and rabbeting cutters from the catalog program, users have all the possibilities of this tool.

LEUCO p-System

New quality dimensions and application possibilities

LEUCO is the first tool manufacturer to produce tools with shear angles of ≥ 55°. We call these tools "LEUCO p-System". The process is called "peeling". This tool is patented.

LEUCO p-System tools are used for

- jointing, rabbeting, dividing, chamfering and grooving

LEUCO p-System tools are used on

- stationary and through-feed machines

- and on table shapers with manual feed.

Industry

Universal application in a wide range of production areas such as carcass lines, individual machining of linoleum, flooring or processing of high-gloss boards. Can be used by joineries as well as by industrial woodworking companies.

In traditional wood-based materials and solid woods LEUCO p-System tools generate:

- brilliant cutting quality currently unsurpassed on the market

- generally a significantly longer edge life than ordinary DIA tools

LEUCO p-System tools open new possibilities and cutting quality dimensions for

- processors of special workpiece materials ("material mix")

- production processes requiring extensive rework

Video

Folder

News

Enthused customers say...

- "Even porous, dark and very difficult cover layers can be machined better than ever with the p-System. And the cutter is running, running, running…"

Office furniture manufacturers - "Up to now, it has been difficult to find a tool for milling cork-coated boards. The cutting quality produced by means of the p-System is the best I have ever achieved in cork."

Specialized carpenter - "The machining of multiplex boards with p-System tools does not longer require polishing."

Manufacturer of table leaves - "No more chipping in the case of end-grain jointing. Not even after more than 1 million parquet scantlings!"

Flooring manufacturer

Awards

- German Innovation Award 2018, Excellence in Business to Business (B2B), Machines & Engineering, LEUCO p-System 06/2018

- Schweighofer Innovation Prize for LEUCO p-System, July 2015

Applications

Application examples

Finished:

Milling in finish-cut quality without postprocessing

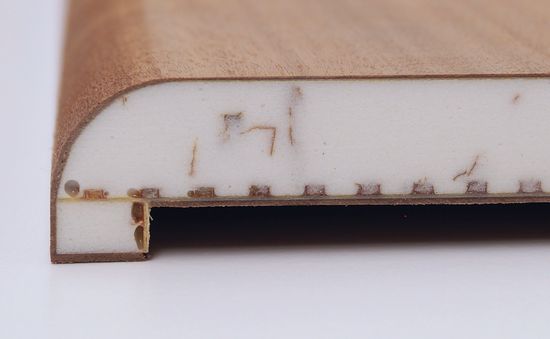

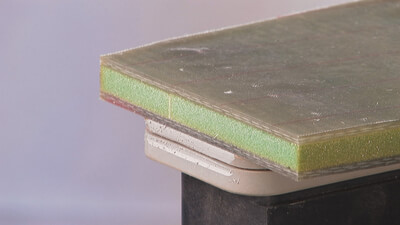

- So far: In the case of Multiplex and plywood, due to veneers glued on top of each other, cutting across and along the grain is made at the same time. This produces a rough edge which had to be resharpened so far.

- Advantage: The p-System produces edges in finish-cut quality, time-consuming sanding is no longer necessary.

Chip-free: chip-free jointing of veneered boards

- So far: Cutting along and across the grain of veneered boards has often caused edge chipping, particularly in the case of jointing of overlapping veneer.

- Advantage: The cutting edges of the p-System cut veneer like a sharp knife. Across the veneer they hardly exert cutting force and make a clean cut, regardless whether the veneer overlap is 2 or 10 mm.

Protection foil: long edge lives in the case of high-gloss material with protection foil

- So far: As soon as the foil was no longer cleanly cut, the tools were changed although the cutting quality of the edge is still o.k.

- Advantage: Thanks to the shear angle design the p-System cuts the foil "sharp as a razor" which allows to benefit from the whole edge life of the cutter.

Exotics: fibrous and exotic materials

- So far: Fabric coatings, leather, lightweight-wood core plywood made from Ceiba or poplar are very fibrous materials; clean milling has been difficult or impossible.

- Advantage: Thanks to the large shear angle the fibers are cleanly cut, often not even postprocessing is needed.

Time-saving: reduction of downtimes

- So far: On working centers, downtimes have been caused by the change of cutters from right-hand rotation to left-hand rotation.

- Advantage: In the case of end-grain cutting, the p-System often allows to pass the edge against the feed without causing edge chipping. This also works with edged workpiece materials depending on edge thickness and board quality. Tool changes are no longer necessary, machine downtimes can be reduced.

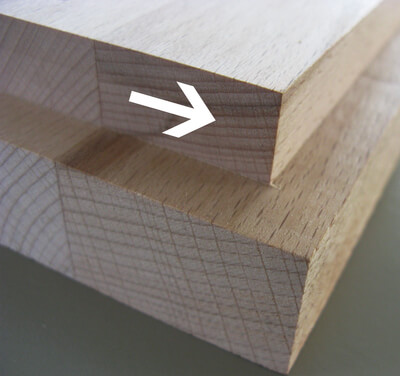

On the machine: Improved chip caption

- So far: The machining of solid wood has been made with the feed. Chips have rarely been captured completely.

- Advantage: Thanks to the p-System the machining of solid wood against the feed is possible which means high chip caption and excellent cutting quality.

- Especially when machining solid wood, peeling creates finer and lighter chips which differ visibly from common chips and which can be extracted more easily.

Applications which have been considered as technically impossible so far

- Machining of solid wood by means of diamond tips with large wedge angle

- Cutting across the grain against the feed without chipping

- Chip-free cutting edge exit when jointing thick edges

- Finish-quality when peeling Multiplex; no additional work steps needed

- Finish-quality when peeling fiber materials such as fabric, laminated panels, linoleum with jute fibers etc.

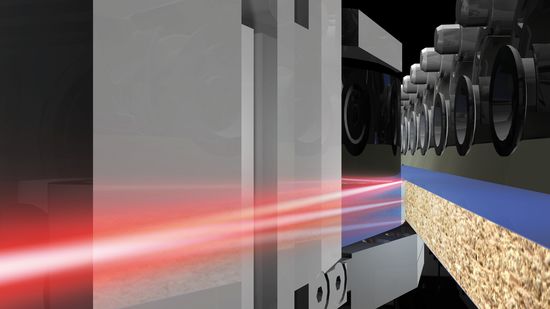

Zero joint with laser - / plasma-technology

- Jointless optics and humidity resistance

The most important advantages of edging by means of laser of plasma- technology are the jointless optics and humidity resistance of the edge. This becomes possible only when optimal jointing quality is achieved. Thanks to the cutting edges with very large shear angle, LEUCO p-System tools cut the surface "like a pair of scissors" with exceptional edge quality. Thanks to the perfect LEUCO p-System jointing without micro chippings, the advantages of laser edging can in fact be benefited from.

Application pictures

The p-System produces edges in finish-cut quality, time-consuming sanding is no longer necessary.

The cutting edges of the p-System cut veneer like a sharp knife. Across the veneer they hardly exert cutting force and make a clean cut, regardless whether the veneer overlap is 2 or 10 mm.

Thanks to the shear angle design the p-System cuts the foil "sharp as a razor" which allows to benefit from the whole edge life of the cutter.

Opening in the same poplar plywood processed by means of a diamond-tipped LEUCO p-System tool. It can be seen and felt that all layers have a smooth and clean surface in spite of the difficult fibrous wood type poplar.

Exotics: Thanks to the large shear angle the fibers are cleanly cut, often not even postprocessing is needed.

In the case of end-grain cutting, the p-System often allows to pass the edge against the feed without causing edge chipping. This also works with edged workpiece materials depending on edge thickness and board quality. Tool changes are no longer necessary, machine downtimes can be reduced.

Oak, milled crosswise to the fibre

Grooving with the LEUCO p-System.

Flooring manufacturer: No more chipping in the case of end-grain jointing. Not even after more than 1 million parquet scantlings!

Foil-wrapped MDF postforming edge milled with the LEUCO p-System, chip-free cutter exit.

What is peeling?

Function and features

Wood processing standard: milling with shear angles of up to 54°

To date, the state of technology considers the positioning of the cutting edge under a shear angle as a "drawing cut". This results from the fact that in the direction of cut, the wedge angle of a cutting edge with shear angle is smaller than the wedge angle of a cutting edge without shear angle.In fact, however, it is just an "inclinated" cut.

Wood processing NEW: peeling with shear angle ≥ 55°

New and unnoticed by the technique is the real drawing cut with the cutting edge being positioned under a very large shear angle. Here, the cutting edge functions like a knife blade, really drawing. The process is patented by LEUCO.

The features of the p-System are achieved by the interaction of the two influencing variables:

- 1. reduction of the effective wedge angle by a large shear angle, i.e. drawing cut

- 2. movement of the cutting edge with regard to the material i.e. scoring cut. The tools do not generate a cutting process in the classical sense - rather a material removal which is similar to peeling.

Peeling with the LEUCO p-System stands for:

- 1. More than a punctual tool improvement with regard to cutting quality, edge life and economic efficiency

- 2. A new type of wood processing apart from sawing, planing and milling

- 3. Increased range of applications for the user which have been considered as impossible so far

Features

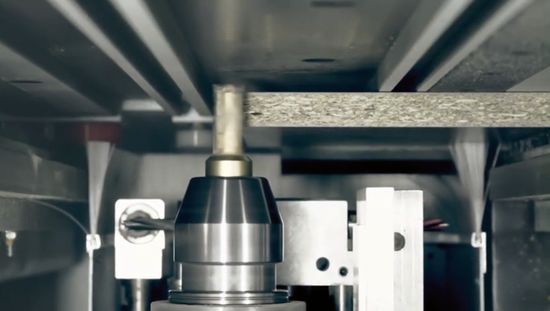

- Uncommon, eye-catching optics of the tools due to the extreme shear angles (shear angle ≥55°)

- cutting material: LEUCO DIA, full height diamond tips

- Sharpening service and sharpening know-how exclusively from LEUCO

Production in Horb am Neckar

The new and - in the woodworking industry - revolutionary shear angle of ≥ 55° implies completely new production processes for the manufacturing of these tools. LEUCO meets these high demands concerning develompent, construction and producion. Well-founded production know-how, a modern tool production facility and persistence are the basis of this revolution.