Sawing of plastics,

Milling and drilling

Magentify Plastics Processing

Sawing

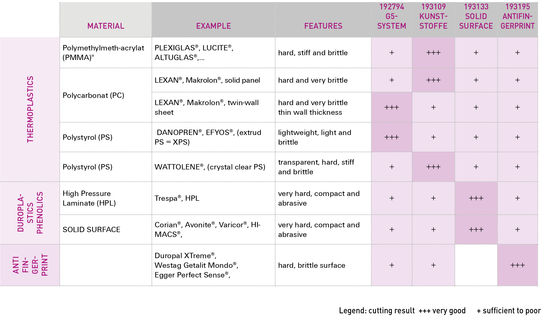

Overview of LEUCO saw blades for plastics

- To enlarge, please click on the picture.

Details of the saw blades

With four circular saw blades, carpenters overcome challenges that arise from the growing use of plastics in furniture and kitchens. After all, plastics have quite different characteristics. For instance, thermoplastics such as polycarbonate and polystyrene easily become too warm and melt when sawed, while thermosets tend to chip.

For use on table saws, vertical panel sizing saws and clipping and miter saws (machine type see description in the online catalog), Leuco recommends:

- Plastics (Article no. 193109)

The “Plastics” saw blade processes all transparent PMMA panels (e.g. PLEXIGLAS®) as well as transparent polystyrene panels (Wattolene). It also saws solid polycarbonate (PC) panels, available under names such as Lexan and Makrolon. Application data such as feed rate, cutting speed, revolutions per minute and saw blade projection can be found in the brochure Plastics processing: Precision tools for milling, drilling and sawing. - LEUCO g5 System (Article no. 192794)

The sizing saw blade “G5” provides the highest quality when sawing thin polycarbonate panels, twin-wall sheets, for instance. Lightweight and brittle panels of extruded polystyrene can also be processed very well with this saw blade. They are commonly found as the Danopren and Efyos brands. - Solid Surface (Article no. 193133)

“Solid Surface” is a saw blade designed for hard and abrasive thermosets. Thus, high-pressure laminates (HPL) can be sawed quickly and with high quality with this blade. It is ideally suited for the mineral-based panels known as Solid Surface, after which LEUCO also named this saw blade. Such panels are available under brand names such as Avonite, Corian, Hi-Macs and Varicor. - Anti-fingerprint (Article no. 193195)

This saw blade offers an excellent cutting quality in “anti fingerprint” materials and for conventional plastics. The convex tooth sides prevent the formation of grooves on the cutting surface and flares on the surface of sensible materials.

Milling

LEUCO VHW shank-type cutters for the

machining of plastics with smooth surfaces

LEUCO VHW shank-type cutters can be used in many ways. They are characterized by high machining quality and a long service life and can be used for high-performance machining:

- On CNC machines

- Z=1 for the processing of plastics, in particular PMMA (e.g. PLEXIGLAS®) for dividing, jointing, rabbeting, grooving, roughing and finishing

- Z=5 for roughing/polishing of PLEXIGLAS®

LEUCO notes regarding the milling of plexiglass on CNC machines

- Material info

PLEXIGLAS® “XT” is more heat-sensitive than PLEXIGLAS® “GS”. Avoid a too low feed rate and/or too high speed. - Milling depth

max. 2 x ØD for one advance. Milling using several advances avoids heating up of chips and cutter. - against feed (GGL) and with feed (GLL)

GGL: recommended with higher feed rates. Chatter marks with too low chip removal.

GLL: for lower feed rates. Irregular milling pattern with too high chip removal, incorrect clamping and/or spindle play; also risk of breakage. - Milling strategies

Pre-milling/roughing: Standard VHW shank-type cutter or plastics VHW shank-type cutter, polished Z=1

Finish-trimming/finishing: VHW shank-type cutter for plastics processing Z=1 (with polished chip chamber) VHW polishing shank-type cutter, polished Z=5. - Console table

Use as many suction devices as possible. Keep workpiece overhang with regard to suction device as small as possible. Cleaning the suction device surfaces with plastic cleaner might improve the result. - Nesting table

Alternative: milling in two steps: cutting depth for roughing approx. 1/10 to 2/10 smaller than panel width. Cutting depth for finishing approx. 1/10 to 2/10 deeper than panel width. - Clamping elements

Precision clamping elements: TRIBOS system, Heat-shrinking chuck, if necessary Hydraulic expansion clamping system - Heat reduction

To avoid heating and any stress whitening, we recommend to use compressed air for chip removal. Suction with the turbine clamping system AEROTECH to remove chips improves milling quality, reduces heating at panel and tool and allows for a longer service life.

Machining information

- Details regarding the milling process, such as revolutions per minute, feed rate and removal and information on the tools can be found in our flyer on the machining of plastics.

Drilling

LEUCO VHW drill bits for plastics

The LEUCO solid tungsten carbide (VHW) dowel bit is characterized by a very smooth cut. When drilling PMMA (e.g. PLEXIGLAS®), the drill bit works with a very low cutting force – depending on the application approx. 1/5 of a standard drill bit.

The VHW body is able to optimally compensate vibrations. The chip evacuation is optimal, multiple hogging is prevented to a large extent which results in a low or only a minimal heating of the heat-sensitive PMMA material and the drill bit.

Machining information

- Details regarding the drilling process, such as revolutions per minute, feed rate and removal and information on the tools can be found in our flyer on the machining of plastics.