Milling, drilling,

countersinking and sawing

of modern lightweight materials

Magentify Composite Processing

Milling, drilling, countersinking

Milling, drilling, countersinking of composites

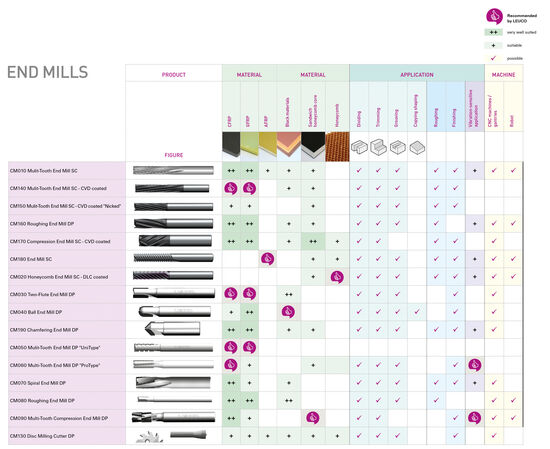

At a glance: cutter program, composite materials, application and machine

- To enlarge, please click on the picture.

- Details on the tools can be found in the brochure (download pdf, page 24 - 37)

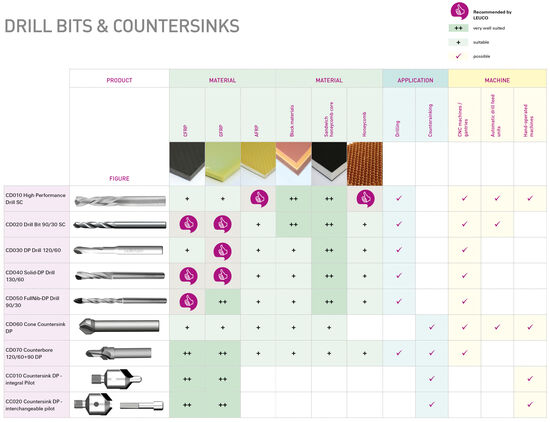

- To enlarge, please click on the picture.

- Details on the tools can be found in the catalog (download pdf, page 11 - 21)

Download

Contacts

Mr Michael Kitzlinger

Global Sales & Segment-Manager Composites michael.kitzlinger@leuco.comM +49 (0) 171 / 356 22 87

Follow US

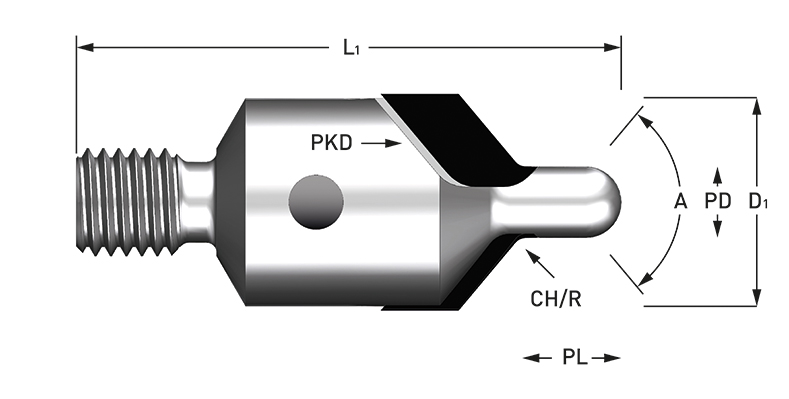

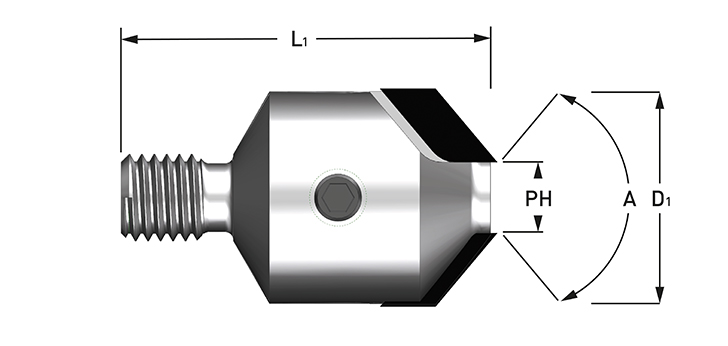

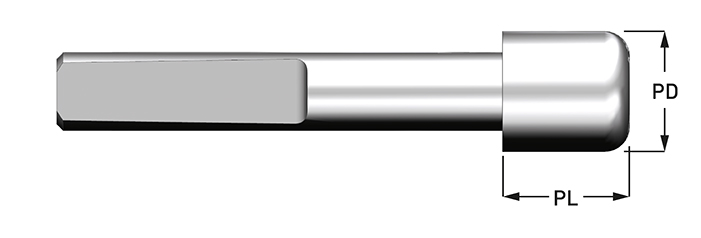

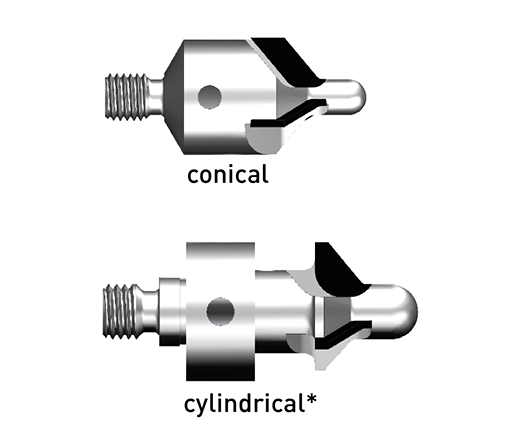

Countersink Guide

Countersink according to customer request

Dimensions

Pilot

Pilot dimensions or bore diameter

Your data

Sawing and accessories

Sawing of composites

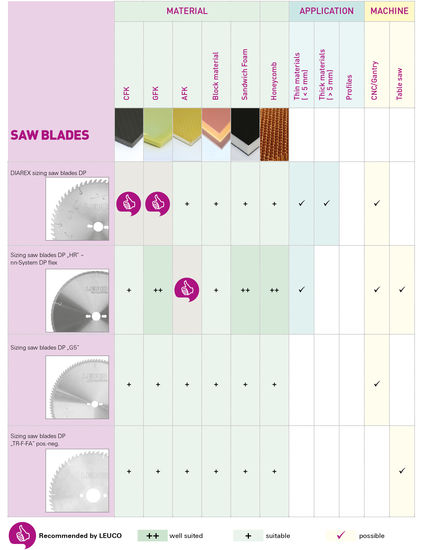

Sawing is a particularly efficient processing method for long, straight contours - this process has established itself especially for honeycomb panels and sandwich structures.

LEUCO offers DP and TC-tipped circular saw blades for this purpose, tailored to almost any material and any application. The tools impress with their high feed rates, excellent cutting quality and long tool life.

An overview of the available variants can be found in the product catalog - our experts will be happy to advise you on the optimum solution.

LEUCO saw blade program for composite materials, application.

- To enlarge, please click on the picture

- Details on the tools can be found in the brochure (download pdf, page 40-42)

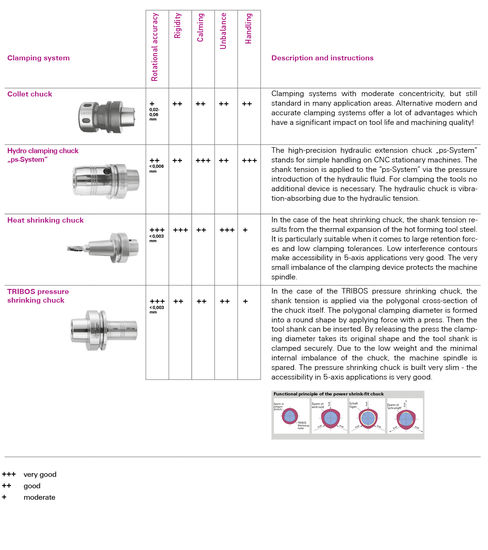

Accessories

But tools are not alone responsible for successful machining. Often, it is only by intelligently combining tools, clamping elements and, if applicable, aggregate technology that the optimal and most economical machining results are achieved. LEUCO relies on modern and highly accurate clamping elements for precision tools which also contribute to your tool's edge life.

At a glance: accessories

- To enlarge, please click on the picture.

- Details on the tools can be found in the brochure (download pdf, page 26)

Download

Contacts

Mr Michael Kitzlinger

Global Sales & Segment-Manager Composite

michael.kitzlinger@leuco.comM +49 (0) 171 / 356 22 87

News

Processing of CFRP, GFRP

The aim is to achieve economical, high-quality machining with low tool wear - for example through the use of PCD and diamond-coated tools.

CFRP

Whether pure CFRP structures or material combinations such as CFRP-aluminum or CFRP-titanium: LEUCO supplies the right tool for every application, even for demanding, tear-free drilling and countersinking in the aerospace industry.

GFRP

Even in dust-intensive applications, optimized tool geometries ensure reliable results - for efficient and reliable GRP machining in series and individual part production.

Download

Contact

Mr Michael Kitzlinger

Global Sales & Segment-Manager Composites

michael.kitzlinger@leuco.comM +49 (0) 171 / 356 22 87

News

Why LEUCO?

Over 70 years of experience

LEUCO has stood for maximum precision in machining technology for over seven decades. Our roots lie in the machining of complex wood-based materials - a know-how that we have consistently transferred to modern lightweight materials.

With over 1,200 experts worldwide and a comprehensive product portfolio of milling cutters, drills, countersinks and saw blades, we offer tailor-made solutions for the most efficient machining of your materials - reliably, economically and with process reliability. LEUCO is your experienced partner in aerospace, automotive and many other industries that rely on modern composite materials.

Consulting - individual solutions for your requirements

Our customers benefit not only from high-quality cutting tools, but above all from our consulting expertise. Over 80 % of all LEUCO products are customer-specific special solutions. Our engineering teams work with you to develop tools that are precisely tailored to your machining processes and materials - for maximum quality, tool life and productivity. Whether initial analysis, test series or optimization of your production line: We rethink processes and support you holistically from the idea to series production.

Technological innovation & over 230 patents

With over 230 patents and industrial property rights, our continuous innovation work is particularly evident in the design of new tool geometries, the use of extremely hard cutting materials such as PCD and specialized coating technologies. Our developments are geared towards the specific requirements of modern lightweight materials. From milling to drilling - we always strive to provide practical and efficient solutions.

- Talk to us about your specific requirements.

Contacts

Mr Michael Kitzlinger

Global Sales & Segment-Manager Composites

michael.kitzlinger@leuco.comM +49 (0) 171 / 356 22 87

Follow us