News

Patent granted for AirStream-System

tools

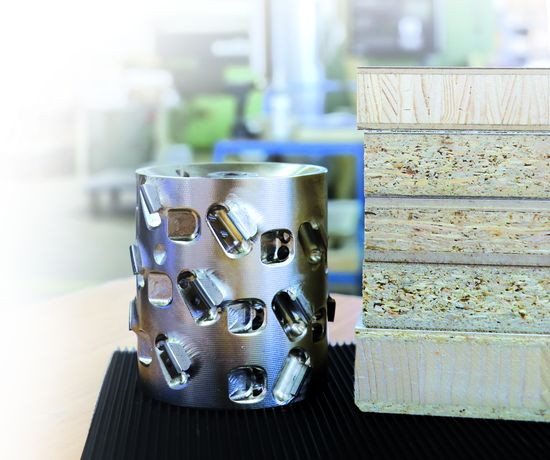

Tools with AirStream-System distinguish themselves by their characteristic bore in the body and are patented by LEUCO and HOLZ-HER. The tools are exclusively available for HOLZ-HER machines.

Jointing cutters and edge trimming cutters with “LEUCO AirStream-System” reduce noise and increase the chip caption degree up to 99 per cent on through-feed machines. The “DIAMAX AirStream-System” jointing cutter has been successfully in operation since October 2016. For the new cutting principle, LEUCO and HOLZ-HER have received an enthusiastic feedback from customers.

Innovation reduces noise and increases the chip caption degree

“LEUCO AirStream-System” tools reduce noise and increase the chip caption degree up to 99 per cent on through-feed machines. This innovation is the result of mutual research and development activities of the tool manufacturers LEUCO (Horb/DE) and HOLZ-HER (Nürtingen/DE). The high degree of innovation of these low-noise and low-emission tools has now been confirmed by a patent of the European Patent Office.

Principle of LEUCO AirStream-System tools

With standard tools, a high pressure area is created on the face. This in turn creates a low-pressure area behind the cutting edge. Both air pressure areas try to level out. The pressure fluctuations are perceived as noise. With “AirStream-System” tools, an intelligent bore at a precisely defined place on the body prevents the creation of air pressure areas. So, no pressure fluctuations are caused. This leads to a measurable sound and noise reduction of 3 dB(A).

Furthermore, the “AirStream-System” exhibits a great degree of influence on the chip flow. The tool rotation has a direct effect on the air flow and guides the chip flow at precisely the right time towards the dust hood air flow. The chip caption degree increases to as many as 97 - 99 per cent. Contamination of machines is virtually a thing of the past. The improved chip direction prevents multiple hogging of the chips. The user can thus benefit from longer tool edge lives.

LEUCO AirStream-System tools for edge trimming and jointing cutting on HOLZ-HER machines

AirStream tools have been developed exclusively for HOLZ-HER through-feed machines. The edge rounding flush-cutting cutters and edge jointing cutters for the units 1826 and 1828 for machining veneer and plastic edges and solid wood edge bands have navigated a successful course on the market since 2013.

For one year, the AirStream family with its characteristic bore has been completing the “DIAMAX AirStream-System” jointing cutters for quiet and chip-free jointing of coated and veneered wood-based materials on the HOLZ-HER units 1801, 1802 and 1804.

“LEUCO AirStream” is a groundbreaking technology for further reducing noise and contamination in production. LEUCO and HOLZ-HER together succeeded in developing an important solution for an urgent problem of the industry. The patented AirStream-System jointing and edge trimming cutters are available from the LEUCO stock.

AirStream patent partner

See our online catalog for dimensions and further details

News Overview

-

Mar 28, 2024

Shank-Type Cutters , Tool News

New nesting cutter Z4+4 based on Fibonacci:

Slim, swift and stable -

Nov 17, 2023

Shank-Type Cutters , Solutions

t3-System cutter with 3D-Holz Design - Perfect milling in wood -

May 8, 2023

Cutter with Bore , Shank-Type Cutters , Solutions

Solutions 8.5 mm grooves in rear panel:

Grooving cutter and shank-type cutter -

May 4, 2023

Shank-Type Cutters , Tool News

DIACURVE: Novel nesting cutter

Perfect cut, easy to handle -

Jul 1, 2022

Boring Bits , Shank-Type Cutters , Tool News

A tool for every application, flexibility as standard -

Dec 6, 2021

Shank-Type Cutters , Clamping Systems , Solutions

Nesting of solid core panels: Application data and tips -

Sep 29, 2021

Cutter with Bore , Shank-Type Cutters , Circular Saw Blades , Clamping Systems , Turnover Knives, Inserts, Knives , Hoggers , LEUCO News

LEUCO review, LIGNA.Innovation Network 2021 -

Sep 22, 2021

Shank-Type Cutters , Tool News

LEUCO t3-System cutters with triangular turnover knife inserts -

Feb 18, 2021

Boring Bits , Shank-Type Cutters , Solutions

LEUCO Tool Alternatives for the New LAMELLO® Cabineo Connector