News

Shop fitter Ruppel: decision in favor of the SmartJointer airFace

The shop fitter Ruppel has several through-feed machines. For several years, the production manager Peter Schultz (left) and the LEUCO tool expert Heiko Späth have been using the diamond-tipped SmartJointer on the edge banding machine. In the past, Schultz tried to stack batch sizes with the same panel thickness in front of the machine and to process them according to the different thicknesses. The use of the SmartJointer now allows them to process the materials flexibly and promptly according to their need in production.

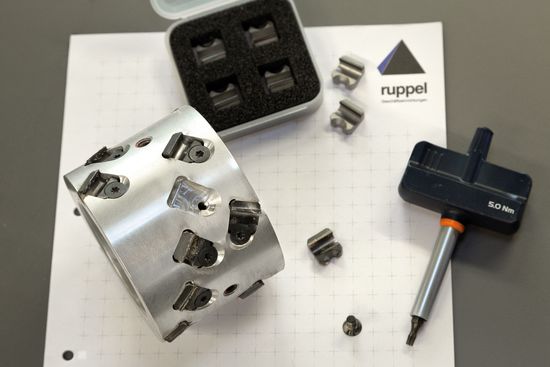

After having been used every day for five years, the SmartJointer from LEUCO looks as good as new. The diamond-tipped cutting edge and the gullet of the SmartJointer form one unit and are replaced during each segment change. This means that the two parts on the SmartJointer that are subject to wear are replaced while the same body is used for years.

The variety of materials which is processed every day in the premises of the shop fitter Ruppel is impressive.

Decision in favor of a superior tool concept:

How the decision in favor of the SmartJointer airFace pays its way

The company Ruppel GmbH in Lauda-Königshofen counts on the jointing cutter SmartJointer airFace from LEUCO. In its premises, not the entire tool but only the cutting edge is replaced. With a flick of the wrist, on site. Therefore, the SmartJointer airFace is always available, thus offering extensive and large benefits.

With about 200 employees, Ruppel manufactures shop equipment and furnishings from single pieces up to series production. The production is equipped, among others, with a CNC machining center and through-feed machines which also include an edge banding machine. From trimming, drilling and milling until edge banding: all required operations are performed in-house. The machines run in 3-shift operation.

Simply ingenious and ingeniously simple: not the tool but only the cutting edges have to be replaced

The SmartJointer from LEUCO is the perfect tool for the edge banding machine of Ruppel. "We process panels with edge thicknesses from 16 mm to 60 mm. The panels most used, however, have a thickness of 19 mm. This means that the cutting edges are exposed to different wear conditions. In the past, we had to replace the cutter although only some of the cutting edges had become blunt," remembers Peter Schultz, master carpenter and production manager of the wood pro-cessing department at Ruppel.

Heiko Späth, master carpenter and the Regional Sales Manager at LEUCO responsible for Ruppel for several years, has the right idea. Why not changing the cutting edges on site if required? This can be done quickly and easily on the jointing cutter SmartJointer from LEUCO. The tool is provided with diamond-tipped segments which are screwed to the tool body. Each machine operator can loosen the segments in a few minutes and insert them again with just a few steps. Segments with blunt cutting edges can be replaced by those whose edges are still sharp or they are replaced by new ones. Since the gullet and the edges of the SmartJointer form one unit, the gullets susceptible to wear are also replaced automatically. A replacement is even possible if the cutting edges are damaged.

Since quality is the most important criterion for Ruppel: the jointing cutter LEUCO SmartJointer airFace is the tool of the future

The LEUCO SmartJointer sets new standards. The reduced machine downtimes and long edge lives of the segments which amount, at Ruppel, to a total of 30,000 to 35,000 running meters speak for themselves. Heiko Späth is impressed: "Our development department has done a great job. The best thing is the shear angle of 35° which is a class of its own". The larger shear angle allows a better cutting quality than the usual shear angle of 30°. The difference is clearly visible on the thin edges.

For Ruppel it is also very important that the tool diameter does not change after having replaced the segments. The advantage: Due to its highly constant diameter, the SmartJointer can be used immediately after segment replacement without machine adjustment. This saves time and means a consistent quality.

The LEUCO SmartJointer is ideal for the high demands of Ruppel. Different panel thicknesses and changing batch sizes are only one reason for this. Another reason is the variety of materials to be processed. These are, among others, particle boards, MDF and HPL panels and particularly abrasive fire protection panels. The top layer (decor) is also responsible for the uneven wear of the cutting edges. The LEUCO SmartJointer tackles the most demanding task. "The new edge banding machine which Ruppel wants to buy will be equipped on both sides with this tool," says the practioner Peter Schultz. This is the best recommendation the LEUCO SmartJointer can ever receive. But improvements have already been implemented: the new SmartJointers are delivered with the low-noise airFace design. airFace can be recognized by the distinctive longitudinal grooves which guide the air flow along the surface.

The SmartJointer provided Ruppel with the right solution expected by the company. This also shows: customized solutions to fulfil special customer requirements is the great strength of LEUCO. The experts listen to the customer and inform themselves on location. So they can understand what the customer needs. Thanks to its experience and competence, LEUCO is able to determine which solutions are possible and implements them. The customer has the good feeling: we can rely on LEUCO.

News Overview

-

Apr 11, 2024

LEUCO News

LEUCO China: New location and building for headquarters -

Mar 28, 2024

Shank-Type Cutters , Tool News

New nesting cutter Z4+4 based on Fibonacci:

Slim, swift and stable -

Dec 6, 2023

Circular Saw Blades , Tool News

Interview: HW-panel sizing saw blade

“Q-Cut G6 Edition” with tool life -

Nov 17, 2023

Shank-Type Cutters , Solutions

t3-System cutter with 3D-Holz Design - Perfect milling in wood -

Oct 25, 2023

Circular Saw Blades , Tool News

LEUCO nn-System DP flex -

Now with new topcoat coating -

Oct 6, 2023

LEUCO News

2003 - 2023

20 years of LEUCO Poland -

Sep 15, 2023

Cutter with Bore , Solutions

Synchronously adjustable with Holtkamp Möbelteile -

Aug 25, 2023

LEUCO News

25 Years Jubilee - A significant milestone for LEUCO Malaysia -

Jun 2, 2023

LEUCO News

LIGNA 2023, review and thanks to our guests