p-System High-Performance Grooving Shank-Type Cutters CM DP

Article

Description

Machine / Application

- CNC stationary machines

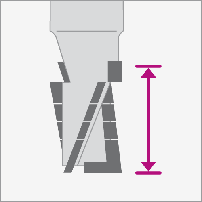

- for grooves, cut outs, pockets and as forend cutter

- for chip-free high-performance grooving of solid woods (free of knots) along and accross the grain

- for high-performance grooving of melamine-, paper-, HPL-laminated, foiled and veneered panels and lacquered surfaces

- Finish-quality in the case of fiber materials such as fabric-laminated panels, linoleum with jute fibers, cork etc.

Design

- extremely scoring cut

Advantages

- maximum cutting quality and edge lives

- chip-free cuts even on the exit side

Notes

- minimal grooving depth 0.5 mm

- as from 25 mm Z=2 is possible, bottom cutting edge is Z=1 always

- convex bottom cutting edge for better bottom quality of rabbet, however corner of rabbet not absolutely sharp

- for ramping or circular plungeing only

- clamping element: precision clamping element e.g. ps-System, TRIBOS, heat shrink-fit chuck

- with thread for length adjusting screw

- sense of rotation according to VDMA 8849

|

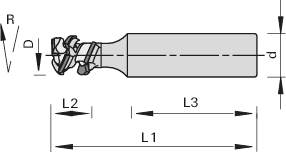

Ø D

[mm] |

L2

[mm] |

Ø d

[mm] |

L3

[mm] |

L1

[mm] |

Z |

nmax

[min-1] |

Shear∡

[°] |

Resharpening area

[mm] |

L/R | Ident-No. | Comp./ Inqu. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Dimensions entered are not listed?

available from stock |

||||||||||||

| 8 | 3,3 | 8,0 | 50 | 65 | 1+1 | 24,000 | 70 | 0.4 | R | 187844 | ||

| 8 | 3,3 | 10 | 50 | 65 | 1+1 | 24,000 | 70 | 0.4 | R | 186095 | ||

| 10 | 4,8 | 12 | 45 | 65 | 1+1 | 24,000 | 70 | 0.9 | R | 186096 | ||

| 10 | 10,4 | 12 | 45 | 70 | 1+1 | 24,000 | 70 | 0.9 | R | 186097 | ||

| 12 | 21,4 | 12 | 50 | 90 | 1+1 | 24,000 | 70 | 1.4 | R | 185506 | ||

| 12 | 10,2 | 16 | 45 | 80 | 1+1 | 24,000 | 70 | 1.4 | R | 185505 | ||

| 12 | 21,4 | 16 | 45 | 90 | 1+1 | 24,000 | 70 | 1.4 | R | 185507 | ||

| 16 | 14 | 16 | 45 | 85 | 1+1 | 24,000 | 70 | 1.9 | R | 185508 | ||

| 16 | 24,4 | 16 | 45 | 90 | 1+1 | 24,000 | 70 | 1.9 | R | 185509 | ||

| 16 | 32,2 | 16 | 45 | 90 | 1+1 | 24,000 | 70 | 1.9 | R | 186098 | ||

| 18 | 19 | 16 | 55 | 95 | 1+1 | 24,000 | 70 | 2.4 | R | 185612 | ||

| 18 | 7,0 | 20 | 55 | 90 | 1+1 | 24,000 | 70 | 2.4 | R | 185613 | ||

| 18 | 19 | 20 | 55 | 95 | 1+1 | 24,000 | 70 | 2.4 | R | 185614 | ||

| 25 | 9,4 | 25 | 50 | 95 | 1+1 | 24,000 | 70 | 2.4 | R | 185615 | ||

| 25 | 18 | 25 | 50 | 100 | 1+1 | 24,000 | 70 | 2.4 | R | 185616 | ||