新闻

Reinhold Keller Group: Relies on Q-Cut G6 panel sizing saw blades

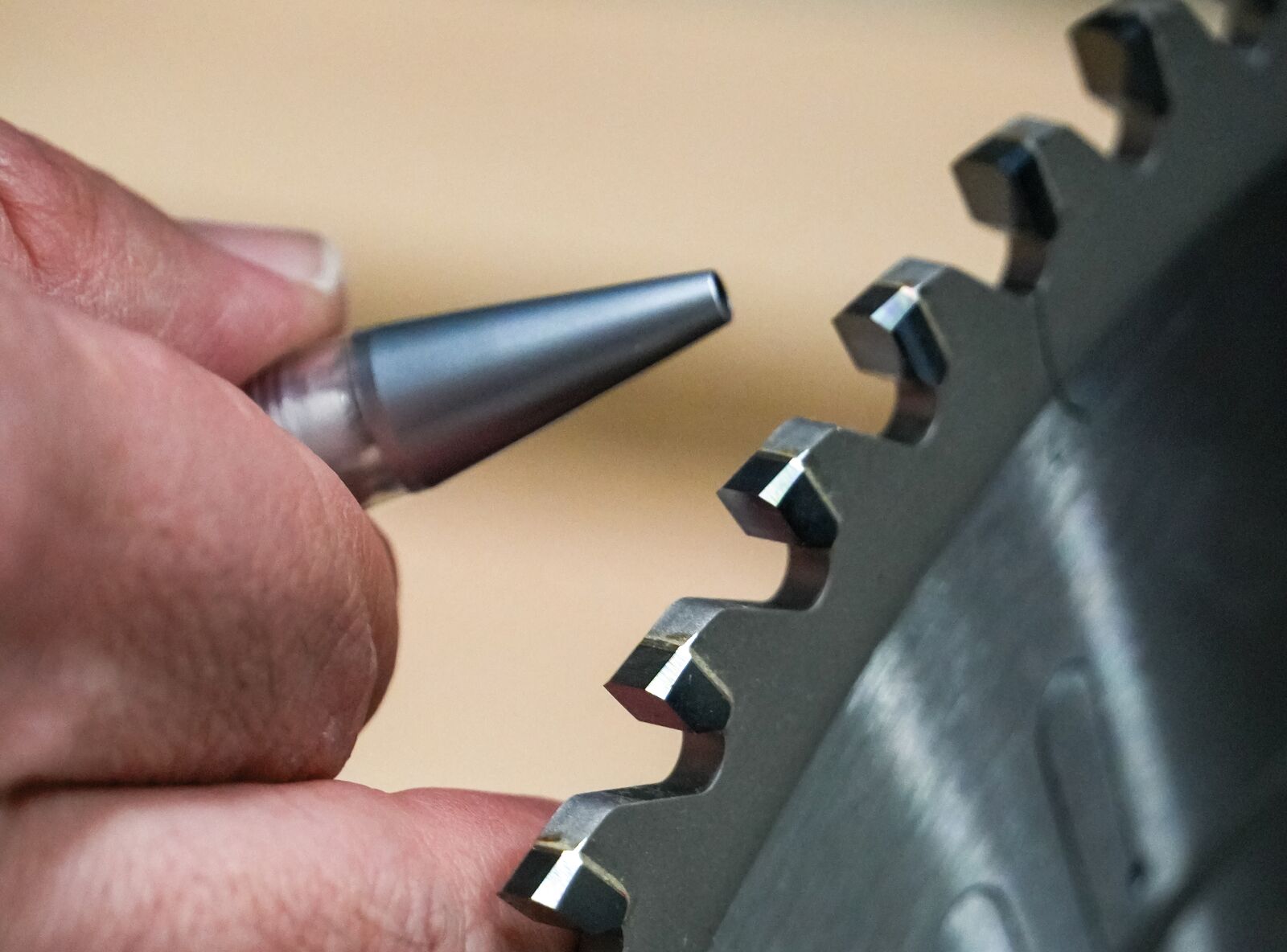

A champion for single panels and packages up to a cutting height of 80 millimeters: The carbide-tipped Q-Cut G6 saw blade from LEUCO offers excellent cutting quality and long tool life thanks to its low vibration and special tooth geometry with two leading and four finishing teeth.

A place of superlatives: The REINHOLD KELLER Group warehouse sets standards in terms of size, automation level, number and variety of panels. Even with the most demanding materials, the Q-Cut G6 saw blade from LEUCO guarantees precise and chip-free cutting.

Production at the highest level: Jürgen Hennig, Machinery Team Leader (right), and LEUCO Regional Manager, Heiko Späth (left) .in the high-tech production facility of the internationally active REINHOLD KELLER Group, which relies on LEUCO tools when equipping its high-performance systems.

Made for top performance: The nesting cutter from LEUCO delivers a perfect edge, including on printed panels with an abrasive top layer. Despite the high mineral content, the cutter processes the panels precisely and without chipping. "It processes an amazing number of running meters", as Jürgen Hennig, Tool Manager from the REINHOLD KELLER Group, emphasizes.

With its "Q-Cut G6" saw blade, tool manufacturer LEUCO is setting new standards in the cutting of coated panels. The saw blade is the preferred tool of furniture manufacturers and interior furnishing specialists thanks to its outstanding quality and reliability for the finish cut. This includes the globally active REINHOLD KELLER Group. As an experienced roll-out partner in interior furnishings for the catering, hotel, fitness and healthcare sectors, the company relies on precise and efficient production processes. The excellent cutting quality of the LEUCO saw blade, which provides clean edges and maximum fitting accuracy, is therefore highly valued - essential for the series production of high-quality interior furnishings.

The Q-Cut G6 saw blade impresses with its innovative geometry and the high quality of the carbide-tipped teeth. The REINHOLD KELLER Group from Kleinheubach in Bavaria appreciates this. The company manufactures furnishings for hotels, catering businesses and fitness centers. Precision and efficiency are the key success factors for the family-owned business and at the same time set the standard for the tools used.

The ideal cut for worldwide production

„We are a global player, deliver to over 90 countries and have state-of-the-art production equipment for which we rely on precision tools from LEUCO," says Jürgen Hennig, Team Leader for Machinery at REINHOLD KELLER. "This," continues the master carpenter, "enables us to achieve results that are fully in line with our understanding of quality." The interior furnishings producer uses the Q-Cut G6 saw blade on his fully and semi-automatic cutting systems. "The saws," says Jürgen Hennig, "are in constant use. Regardless of whether we are cutting a larger quantity or a single panel. You can always rely on the Q-Cut G6 to do this precisely and efficiently."

Economical and powerful for every challenge

The price-performance ratio is also right, emphasizes Jürgen Hennig. New purchases and resharpening paid off. This is an important factor in view of the high load on the tools caused by the large processing quantities and the challenging sheet material, which contains an increased amount of foreign matter. "We always run two shifts and need around two to three saw blades per day on each machine. Because of the high processing volume and the increasingly demanding nature of the panels, we check the tools every quarter of an hour or so and change them sooner rather than later," emphasizes the master carpenter. In this way, the company ensures consistent quality of the finished cuts, even with an extremely demanding mix of materials. For example, solid core panels and wood core plywood (blockboard) with or without an HPL coating, 3-layer panels and particle board with all common surfaces can be sawn without changing the saw blade. According to Jürgen Hennig, with the G6 a user "can process an average of around two to two and a half thousand running meters before the saw blade needs resharpening.“

Precision and durability thanks to advanced saw blade technology

The tool always produces excellent results. "The high cutting quality," explains Heiko Späth, LEUCO Regional Manager and master carpenter himself, "results from the low vibration of the tool body. In addition, the saw blade has a smooth-running tooth geometry that ensures long tool life thanks to two leading teeth with increased cutting performance and four trailing teeth for the finish cut." According to Späth, the Q-Cut G6 saw blade is perfect for processing both single panels and stacks with a cutting height of up to 80 millimeters. He adds: "The special LEUCO carbide also makes the tool resistant to breakage and impact."

Good cooperation for maximum reliability

In addition to the outstanding products from LEUCO, the master carpenter emphasizes the reliability of the tool supplier in Horb. Jürgen Hennig: "It just works really well. If I have a problem or am missing a tool, then Sales, Service or the office staff will help me immediately. Everything possible is done to provide me with a replacement tool quickly. As a customer, I feel very well looked after." The personal contact with LEUCO is highly valued at REINHOLD KELLER and also contributes to the success of the company, which is now being managed by the 6th generation, summarizes Hennig.

A complete range of tools from LEUCO

Thanks to the high level of quality and service, the interior furnishings expert relies entirely on LEUCO products, including hoggers, jointing and flush-cutting tools, scraper blades as well as rounding and diamond-tipped tools, from its CNC machining center to its through-feed machine. "For nesting, we rely on the high-speed cutter from LEUCO," explains Tool Manager Hennig. "It ensures an impressive number of running meters processed - even with demanding surfaces, such as those found on the printed panels from MB Digitalprint, a company of the REINHOLD KELLER Group. The top layer is extremely abrasive due to the applied clear coat, which has a high proportion of mineral corundum. Nevertheless, the cutter runs through it phenomenally - just like the G6 saw blade on every one of our panels."

photos: REINHOLD KELLER Group

新闻概览

-

2025年6月23日

解决方案

Composites processing: New catalog "CP 06", new VHW tools -

2024年5月2日

圆锯片 , 解决方案

Saw blade HW TR-F-K at Schüco Interior Systems KG: Precise cutting in light metals -

2023年11月17日

柄铣刀 , 解决方案

t3-System cutter with 3D-Holz Design - Perfect milling in wood -

2023年9月15日

带孔的铣削刀具 , 解决方案

Synchronously adjustable with Holtkamp Möbelteile -

2023年5月8日

带孔的铣削刀具 , 柄铣刀 , 解决方案

Solutions 8.5 mm grooves in rear panel:

Grooving cutter and shank-type cutter -

2021年12月6日

柄铣刀 , 夹紧系统 , 解决方案

Nesting of solid core panels: Application data and tips -

2021年2月18日

钻头 , 柄铣刀 , 解决方案

LEUCO Tool Alternatives for the New LAMELLO® Cabineo Connector -

2020年8月20日

钻头 , 柄铣刀 , 圆锯片 , 解决方案

塑料的铣削、钻孔与切锯:刀具与应用数据