News

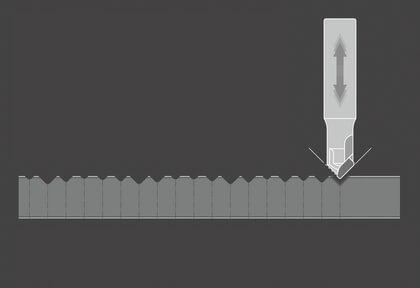

Relief image technology is a computer-supported process for transferring image information to plate materials by means of CNC cutting technology, e.g. with the Pic2Plate light-reflex-gravure software from LettnerWorx.

The diamond-tipped LEUCO relief image cutter is ideal tool for V-groove cuts on CNC machines in the widest variety of materials.

Design and Advantages

DP cutting material: very long edge lives particularly in hard panel materials

LEUCO topline design: optimal cutting quality through specialized blade preparation

Resharpening area 2 mm; resharpenable multiple times, very long tool life

Detailed info on the LEUCO relief image cutter in the LEUCO online catalog

Optimal performance is achieved by using the cutter in highly precise clamping elements.

LEUCO recommends:

Hydraulic expansion clamping chuck "LEUCO ps-System," HSK 63F

Power Shrink Chuck "TRIBOS," HSK 63F

Usage recommendations

Guidelines for feedrate in dependence on RPM and plate material used. The specified values are considered to be guideline values.

- HPL compact plates: RPM 18.00 = feed 5 m/min, RPM 24.000 = feed 7 m/min

- CDF (Compact Density Fibreboard): RPM 18.00 = feed 6 m/min, RPM 24.000 = feed 8 m/min

- MDF melamine-laminated: RPM 18.00 = feed 7 m/min, RPM 24.000 = feed 10 m/min

LEUCO Tip

For the best possible cutting result when processing on console table machines:

Ensure maximum possible fastening of the plates with a sufficient number of suckers, identical sucker heights, clean sucker surfaces, also using aluminum suckers as applicable.