News

LEUCO jointing cutter with HSK 32 interface used at Ewert Ladenbau

For Peter Ewert, the quality of store furnishings and kitchens must be perfect.

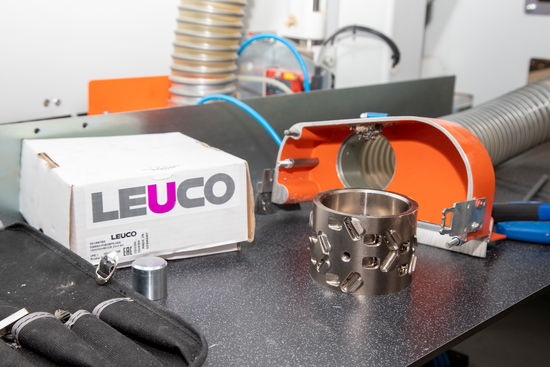

Tony Hermann, Ewert employee, prepares a new order on the machine from HOLZ-HER with the new DIAMAX AirStream HSK 32 F jointing cutter.

High precision despite simple handling: The DIAMAX AirStream HSK 32 F jointing cutter from LEUCO can be clamped in the machine quickly with an Allen key.

The use of the HSK 32 tool adapter instead of the classic double keyway reduces the radial runout of the LEUCO DIAMAX AirStream jointing cutter from 60 µm to 20 µm.

Lord Lorenz easily cleans the machine and the LEUCO jointing cutter using a compressed air gun.

The precision HSK 32 tool adapter, shown here on the machine from HOLZ-HER, ensures minimal radial runout.

The jointing cutter, air flow and dust extraction are closely matched to one another. As a result, the level of chip capture is a solid 97 %. The machine hardly ever becomes soiled.

"Visibly better quality"

High-quality store furnishings and interiors are a specialty of Peter Ewert. The optics of the edges produced plays an important role when it comes to their quality. That is why he relies on the LEUCO DIAMAX AirStream jointing cutter with precise HSK 32 tool clamping.

For a long time, only jointing units on large machines were equipped with the high-precision HSK tool adapter. Despite this, HOLZ-HER introduced the smaller HSK 32 clamping on its more compact edge banding machines for tradesmen. And now, LEUCO has adapted the DIAMAX AirStream jointing cutter to this interface. The combination of tool and tool adapter achieves a radial runout of at most 20 µm – compared to the 60 µm of a classical double keyway tool adapter.

High expectations with HSK clamping

At his specialized plant in Genthin, Saxony-Anhalt, where he produces primarily store furnishings and interiors, Peter Ewert already had good experience with HSK tool adapters in the past. For this reason, he was very interested when he learned about the new development while looking for a new machine at HOLZ-HER. The manufacturer had announced an edge banding machine with HSK 32 tool clamping and a jointing cutter from LEUCO. The reduced radial runout through use of HSK clamping promised an even better appearance at the transition from the edge to the top layer on the workpiece. As a result, Peter Ewert immediately decided to purchase the new machine-jointing cutter combination: "I preferred to have the first new machine rather than the last old one".

For Peter Ewert, clean, precisely produced edges are very important – and this is clear from his orders. For instance, he has produced furniture for opticians as well as jewelry and leather goods stores; here, the quality of the stores furnishings must make a good impression.

Quality benefits from minimal radial runout

"We are a third-generation family-owned operation. Proper edges on the workpiece were always important for us, as this is the quality characteristic for the customer and what he pays for", explains Peter Ewert. "With the new machine, the quality has become visibly better; rework is not necessary. This saves time and money – jointing panels, producing edges, flush routing, rounding and finished."

Production is also cleaner with the LEUCO DIAMAX AirStream. Thanks to the AirStream system, which has been designed specifically to remove chips from the tool area and convey them to the machine extractor, LEUCO and HOLZ-HER have been able to increase the level of chip capture to 97 to 99 %. As a result, most chips are conveyed to the dust extraction and the machine can be cleaned faster after the work has been completed.

Furthermore, with its control of the air flow AirStream reduces the noise generated by the jointing cutter. "Our foreman noticed this immediately while passing through production", reports Ewert: "He said that the machines are noticeably quieter."

News Overview

-

Jun 25, 2025

Circular Saw Blades , Solutions

Reinhold Keller Group: Relies on Q-Cut G6 panel sizing saw blades -

Jun 23, 2025

Solutions

Composites processing: New catalog "CP 06", new VHW tools -

May 31, 2024

Shank-Type Cutters , Solutions

Milling advanced materials with thin diameters -

May 2, 2024

Circular Saw Blades , Solutions

Saw blade HW TR-F-K at Schüco Interior Systems KG: Precise cutting in light metals -

Nov 17, 2023

Shank-Type Cutters , Solutions

t3-System cutter with 3D-Holz Design - Perfect milling in wood -

Sep 15, 2023

Cutter with Bore , Solutions

Synchronously adjustable with Holtkamp Möbelteile -

May 8, 2023

Cutter with Bore , Shank-Type Cutters , Solutions

Solutions 8.5 mm grooves in rear panel:

Grooving cutter and shank-type cutter -

Dec 6, 2021

Shank-Type Cutters , Clamping Systems , Solutions

Nesting of solid core panels: Application data and tips -

Feb 18, 2021

Boring Bits , Shank-Type Cutters , Solutions

LEUCO Tool Alternatives for the New LAMELLO® Cabineo Connector