News

Clockwise and counter-clockwise rotation with a single cutter Z=2+2

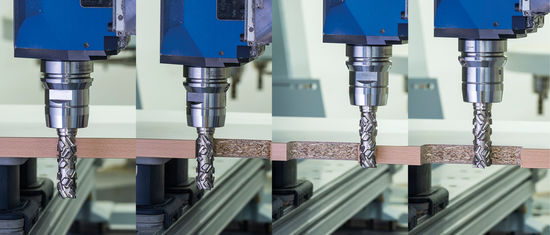

Insert milling is a classic application for the new clockwise/counterclockwise router: Routing with the upper, clockwise-rotating cutting segment with a conventional cut. Then raising the spindle in the Z-direction, followed by reversing the direction of rotation to the counterclockwise direction. Routing with a conventional cut from the right side with the lower, counterclockwise-rotating cutting segment.

The new router bit generation is available in two sizes from stock. One version for processing material thicknesses up to 19 mm, another for thicker material up to 32 mm.

DP DIAREX combination shank-type router bits

LEUCO introduces two new combination shank-type router bits with clockwise/counter-clockwise rotation for sizing and joining of panel materials on CNC machines with console tables. The shank-type router bits have both a counter-clockwise rotating and clockwise rotating cutting segment, each of which can be used by shifting along the Z-axis and changing the direction of rotation.

When routing workbench board corner connections in particular, this guarantees chip-free cutting of the visible edge by routing both sides with a conventional cut using only one router bit.

The customer thus no longer needs two separate tools, saves the time associated with a complete tool change and, in addition, gains a free location on the tool changer.

The proven DIAREX cutting edge geometry with large opposite shear angles ensures exceptionally clean edges even in the case of fragile coatings. Thanks to the compact design of the base body, the router bit provides high stability, ensuring smooth running.

News Overview

-

Jul 2, 2025

Shank-Type Cutters , Tool News

Trio cutter: Precision and power for magnetic bond board -

May 31, 2024

Shank-Type Cutters , Solutions

Milling advanced materials with thin diameters -

Mar 28, 2024

Shank-Type Cutters , Tool News

New nesting cutter Z4+4 based on Fibonacci: Slim, swift and stable -

Nov 17, 2023

Shank-Type Cutters , Solutions

t3-System cutter with 3D-Holz Design - Perfect milling in wood -

May 8, 2023

Cutter with Bore , Shank-Type Cutters , Solutions

Solutions 8.5 mm grooves in rear panel:

Grooving cutter and shank-type cutter -

May 4, 2023

Shank-Type Cutters , Tool News

DIACURVE: Novel nesting cutter

Perfect cut, easy to handle -

Jul 1, 2022

Boring Bits , Shank-Type Cutters , Tool News

A tool for every application, flexibility as standard -

Dec 6, 2021

Shank-Type Cutters , Clamping Systems , Solutions

Nesting of solid core panels: Application data and tips -

Sep 29, 2021

Cutter with Bore , Shank-Type Cutters , Circular Saw Blades , Clamping Systems , Turnover Knives, Inserts, Knives , Hoggers , LEUCO News

LEUCO review, LIGNA.Innovation Network 2021 -

Sep 22, 2021

Shank-Type Cutters , Tool News

LEUCO t3-System cutters with triangular turnover knife inserts